Your Shed Needs a Solid Foundation

We want to help you reach your goals, from the initial design of your building to the eventual delivery and long term use and satisfaction. A well-prepared shed foundation will help your garden shed sit level and protect it from warping over time.

Whether you’re into using concrete blocks, gravel, or a cement pad, we’re glad to help you understand how to prepare for your new outdoor storage shed.

If you need someone to prepare the site for you, we may be able to help with that as well. See below for more information. Photo Credit: Site Preparations

How do I prepare my site prior to the delivery of the building?

You will need a level spot for the building. If you place your building on cement, asphalt, or gravel you do not need any concrete blocks placed under the runners. If you are placing your building over grass or dirt, you may choose to use either concrete blocks to place under the runners or prepare a bed of gravel.

Option #1 Place Your Shed on Gravel

On the larger portable storage buildings (with 4 or more runners) it may be easier for you (and our driver) if you spread gravel (3-5″ thick) where the building will rest instead of using blocks.

We recommend gravel called “¾ minus” – this means the largest gravel size is 3/4″ and includes smaller filler gravel mixed with it. Ensure the gravel is level. Whichever method you choose, be sure the spot is level!

Option #2 Place your Shed on a Cement Pad

We can say that pouring the cement slab is the most permanent way to prepare the site. It will last longer for your tool shed and probably the best way to prep your site. We highly recommend this way of preparation for better results.

If you want to know more about how to pour concrete shed slab, click here to read more.

Option #3 Place your Shed on Concrete Blocks

If you choose to use concrete blocks, you will need to place cement patio-paver style blocks under the runners. This can be accomplished by simply digging down to remove excessive dirt, grass, etc. You will need to place concrete blocks (recommended 2″ thick x 8″ wide x 16″ long) under the area where each runner will go.

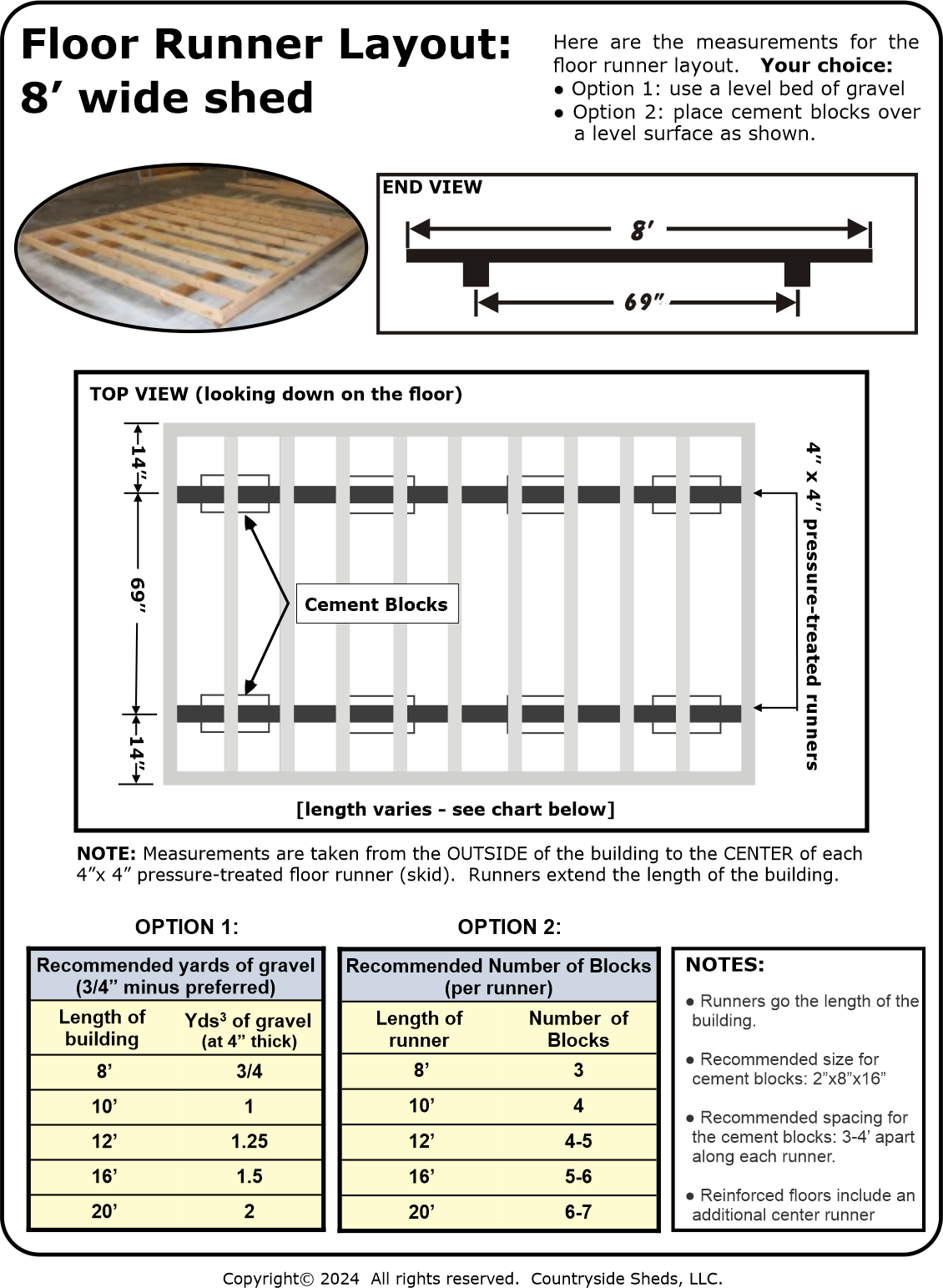

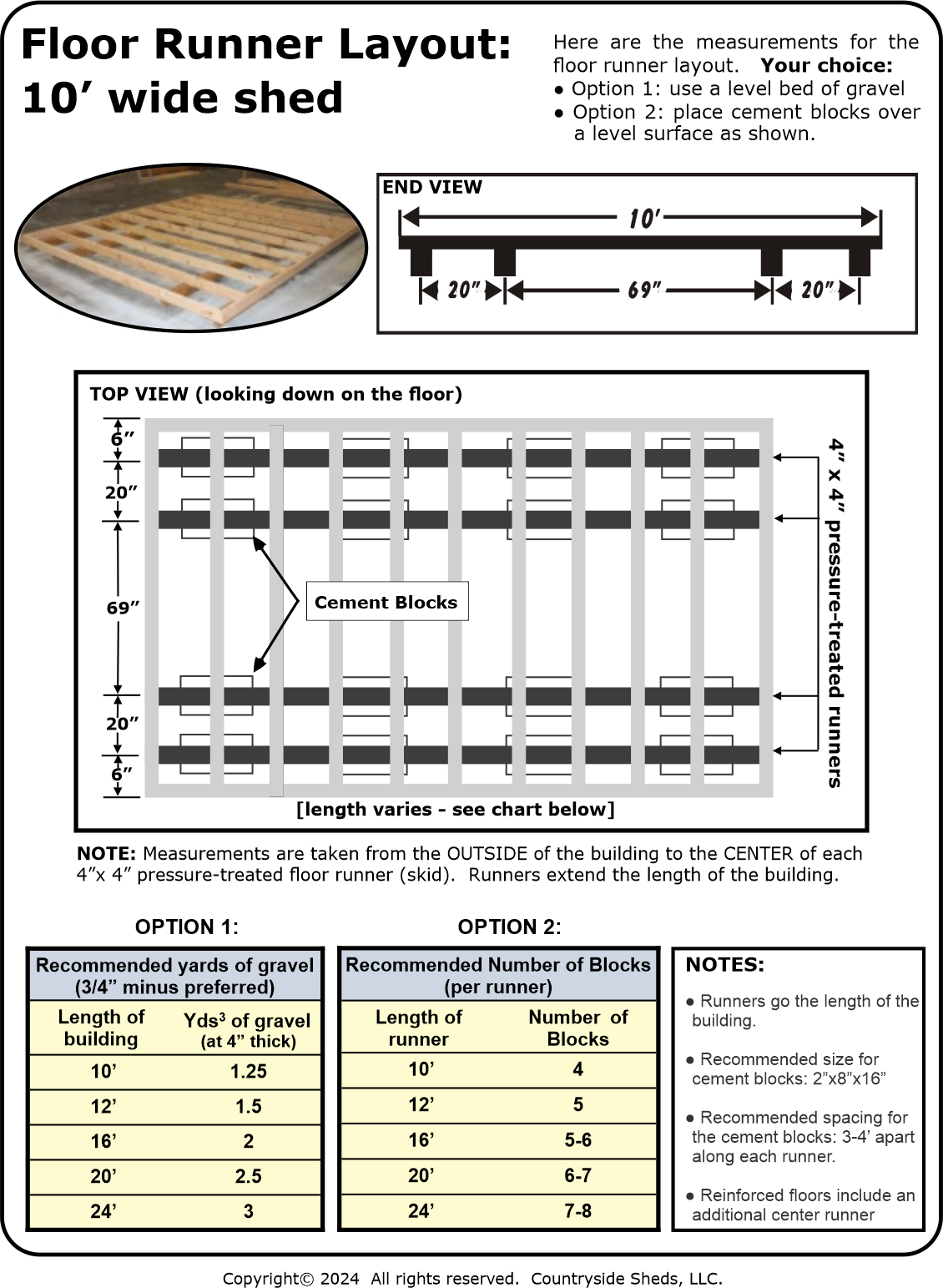

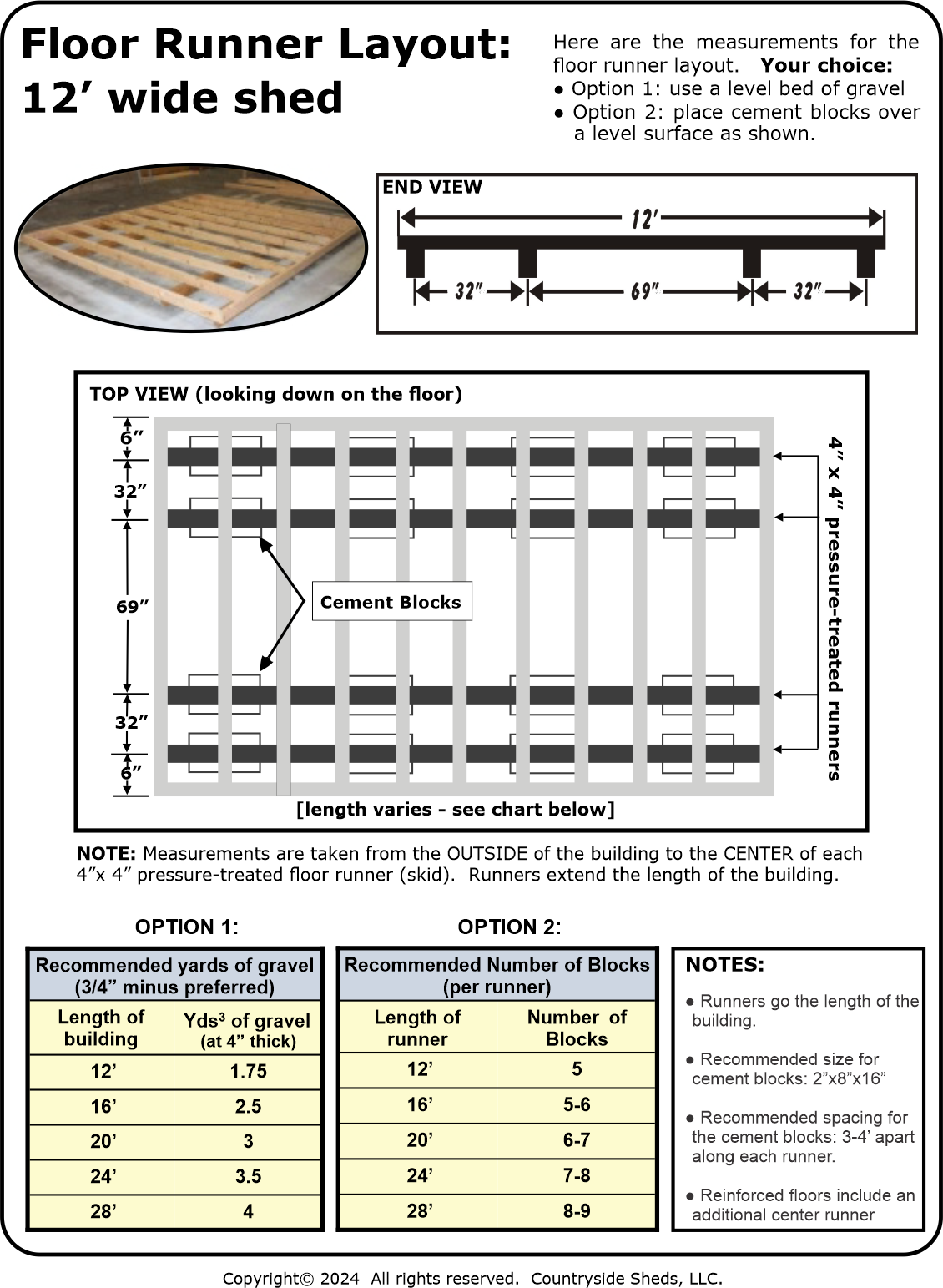

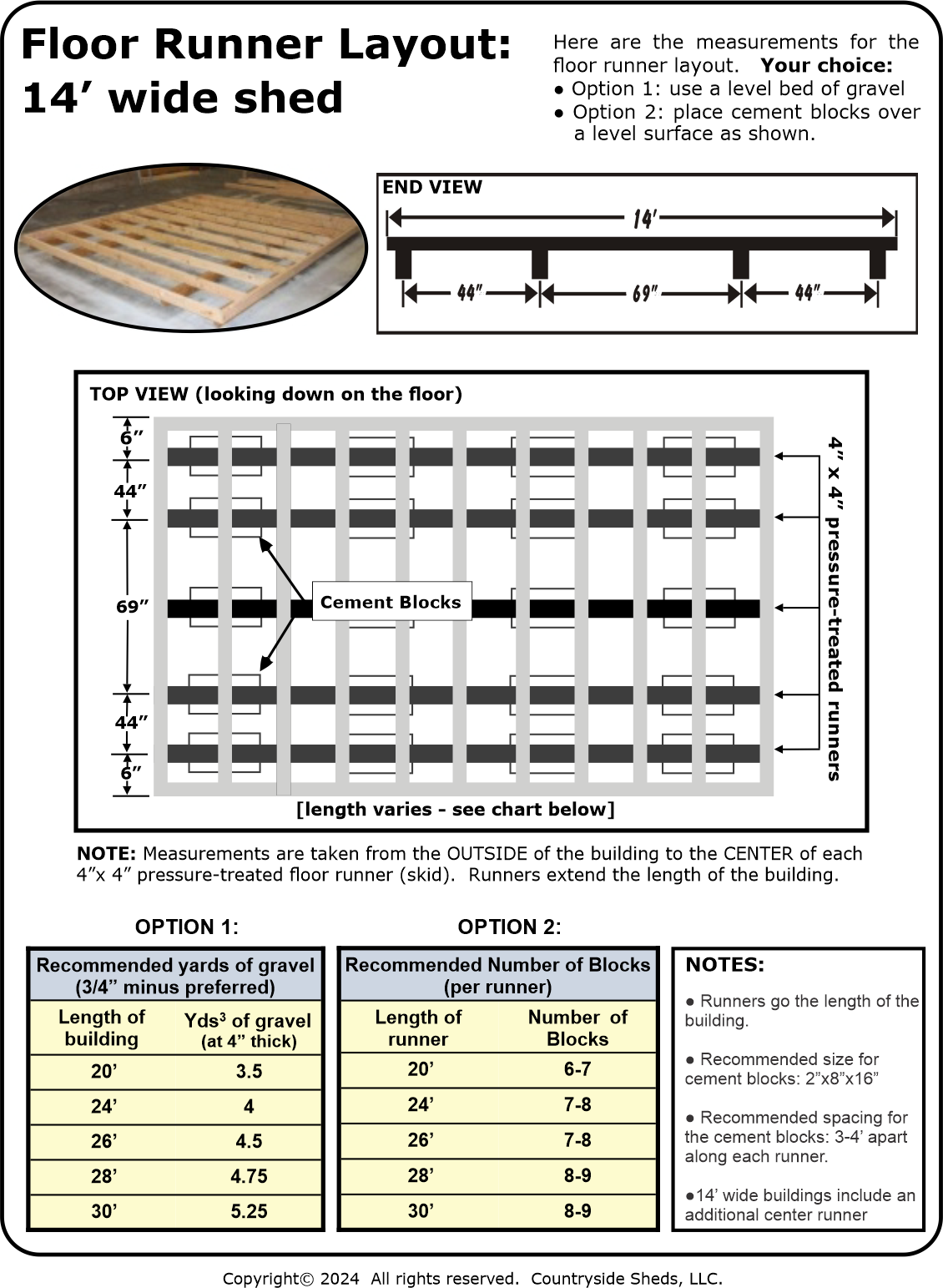

See below for further information on runner layout measurements. Ensure these blocks remain level along the path of the runners. Also cross-check the width for level and from corner-to-corner. Any humps or dips will need to be leveled.

Questions & Answers

What if I want to get a building without a floor and pour a cement slab—how do I do that?

Two things to consider:

- Are you going to have a cement walkway around the shed?

- Are you making the slab just for the building only?

If you are going to have a cement walkway around the shed, pour the slab so the “floor” portion of the slab (where the building will be placed) is flat and level. Taper the cement walkway area slightly away from the “floor″ section for proper rain runoff.

If you are pouring just the slab for the building, frame your slab for the exact size of the “footprint” of the building. Dig around the perimeter of the slab area a little deeper and wider. You will want to pour what’s called a “monolithic″ slab.

For instance, if you are pouring a slab for a 10′ × 12′ building, the slab should be at least 4″ thick minimum. But around the outer perimeter edge dig several inches deeper (about 10″ – 12″ wide and 8″ deep starting from the outside of the edge of the slab.) This requires no additional framing for a foundation stem wall. When you pour the slab, the cement will fill this “footing″ at the same time reinforcing the perimeter edge of the building where the walls will stand.

When the building is placed on the slab, the overall width of the building will now be ½″ wider on all sides (due to the thickness of the siding) than the slab and will allow water runoff to deflect away from the cement, reducing the chance of water seeping into your building. A sill seal barrier strip is also provided that is placed between the pressure-treated bottom sill plates and the concrete.

What are the measurements for the floor runners (skids) so I can lay the blocks?

Click on the corresponding link below for a pop-up window that will show the measurements of the floor runners. Please note that the number of concrete blocks may vary depending on your building length from that shown.

Refer to the accompanying chart for the recommended number of blocks. Simply place the concrete blocks every 3-4 feet along each runner shown. [Please note: to view these pages, you may need to enable “Pop-ups” if your Internet browser setting has them disabled.

Also note that if your building has the reinforced floor (like the garage buildings have), there will be an additional center runner as well.

If I can’t level it myself (or don’t want to mess with it!) can you guys do it for me?

We can provide block leveling if the area is already mostly level, and have equipment and experience for constructing gravel pads. We charge an extra fee for any leveling or site work, in order to cover the cost of our time and materials. The price estimate will obviously vary from job to job. Call for details.

If major excavation is required (trees removed, hillside leveled, etc.), you will need to arrange an excavator to perform that prior to delivery. We may be able to recommend several reliable contractors, if necessary.

Do I need a permit for my building?

Countryside Sheds, LLC wants to be sure that your purchase, delivery and and use of your building meets your expectations. However, please be aware that it is your responsibility to determine whether or not you will need a building permit. Most people do not need a permit.

However, it is your responsible to determine what the requirements are to meet local building codes or other rules that apply in your locality and for any neighborhood covenants, set-backs and site preparation requirements.

Please determine your local building rules and regulations concerning installation before considering a purchase. Additional local housing restrictions, ordinances, or homeowner association guidelines may apply as well.

In Oregon, per “2017 Oregon Residential Specialty Code”, Section R105.2, most areas will allow up to 200 square feet (example 10′ x 20′ building) or an average roof height of 10 feet before needing a permit. Commercial buildings are limited to 120 square feet. Other state’s requirements may vary. More and more counties are now requiring a permit regardless of the size of the building and regardless of whether they are ‘portable’ or not.

If a permit is required, we will try to assist in what ever manner necessary. A simple multi-page CAD drawing can be provided to help assist you with obtaining a permit. Please check with your building department prior to placing an order to see if you will be required to get a permit. Permit fees are the responsibility of the customer. Most agricultural-zoned land may be exempt if placing a building there, provided the building is used for agricultural storage.

Local zoning ordinances, set back requirements, regulations, restrictions, covenants, and other codes or rules that apply to storage buildings (even portable ones) vary from state to state and even from locality to locality within those states. These ordinances are subject to change.

From our experience, the Building Department personnel appear to interpret the building codes differently in each county. Some additional framing may be necessary to your building if you require a permit. (For example, you may need to upgrade to pressure-treated flooring, engineered trusses, 16″ on-center stud spacing or tie-downs to secure your building, etc.)

These may require an additional surcharge to your proposal. Countryside Sheds, LLC understands the frustration and inconvenience this may cause you; therefore, to avoid this, please confirm that the building will meet these requirements prior to purchase. Countryside Sheds, LLC cannot be held liable nor responsible for your decisions in this matter.

The local building department said I had to anchor the building with tie-downs. What do you recommend?

More and more counties are requiring buildings to be anchored. There are several methods of securing the building.

You can dig a post hole at least 2’ deep at each corner of where the building will set. Place a 1/8″ or 3/16″ cable at least 60″ long in the hole – leaving the loose end exposed. Fill the hole with suitable concrete. Once the building is delivered, feed the loose end of the cable around the runner and secure with suitable cable clamps.

Countryside Sheds LLC now stocks both 3″ and 4″ steel anchors with 1/8″ or 3/16″ cables attached. These are simply driven in the ground with a sledge hammer. The loose end of the cable is then wrapped around the runner and secured with cable clamps. These are military-grade and meet code for all locations. Call for pricing.